GST NO. : 33BGNPN4798L1ZJ

| Business Type | Exporter, Supplier, Retailer, Trader |

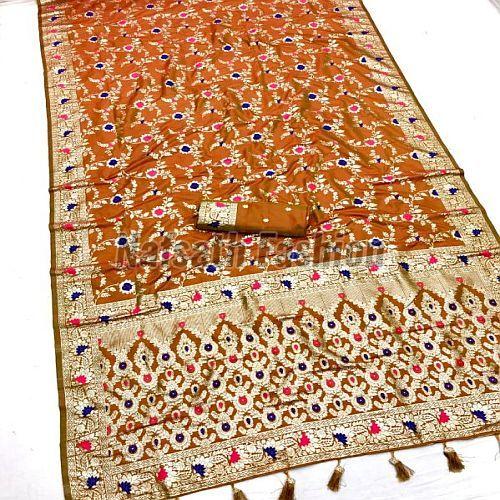

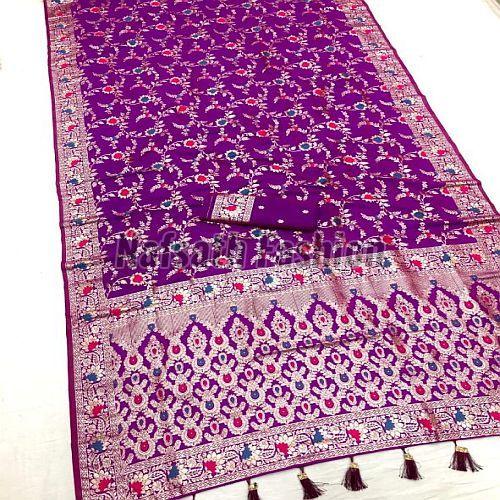

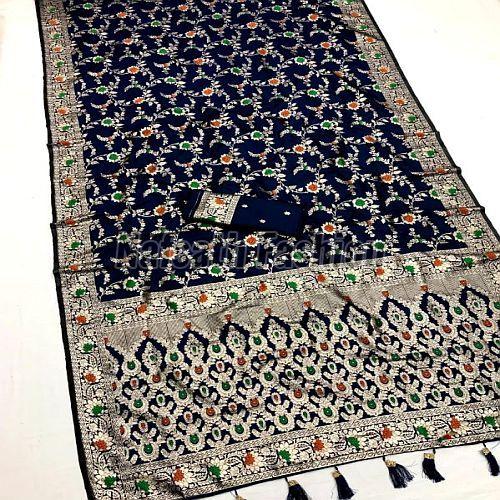

| Pattern | Designer |

| Set Content | With Blouse Piece |

| Saree Length | 6.3 M (with Blouse Piece) |

| Click to view more | |

Product Details

Wash Care

Machine Wash

Feature

Shrink-Resistant

Material

Silk

Color

Available in a variety of colors

Creating a Banarasi sari is a labor-intensive process that often takes weeks or even months, depending on the complexity of the design. The key steps involved are:

- Sourcing Raw Materials: High-quality silk threads are primarily sourced from Karnataka and West Bengal. Zari, the metallic thread, is made by wrapping fine silver or gold around a cotton or silk core.

- Designing the Motifs: Skilled designers create intricate patterns inspired by nature, Mughal art, and geometric shapes. These designs are transferred onto paper, serving as a blueprint for the weavers.

- Preparing the Loom: The silk threads are dyed in vibrant colors and then stretched onto the loom to form the warp (vertical threads) and weft (horizontal threads).

- Weaving: Expert weavers interlace the warp and weft threads on traditional handlooms or power looms, meticulously following the design. Techniques like kadhua (individual motif weaving) and jangla (all-over pattern weaving) are used to create elaborate designs.

- Adding Zari Work: Metallic threads are skillfully incorporated into the weaving process to highlight the motifs and add a touch of luxury.

- Finishing: Once the weaving is complete, the sari is cut from the loom, and any loose threads are trimmed and finished.

Looking for "Floral Design Multicolor Banarasi Silk Saree" ?

piece